Visual inspection, a primary method for defect detection, relies heavily on human accuracy, yet human factors like perception, cognition, and environmental conditions often lead to inspection failures, highlighting the need to address these elements to improve reliability and reduce errors in quality control processes․

Importance of Visual Inspection in Quality Control

Visual inspection plays a critical role in ensuring product quality and safety by detecting defects and deviations early in the production process․ It is a non-invasive, cost-effective method that allows quick assessments of surface conditions, making it indispensable in industries like manufacturing, aerospace, and healthcare․ By identifying issues such as cracks, irregularities, or contamination, visual inspection helps maintain high standards and prevents defective products from entering the market․ Its efficiency lies in its ability to cover a wide range of defect types and severities, ensuring comprehensive quality control․ Despite its reliance on human accuracy, visual inspection remains a cornerstone of modern manufacturing, enabling companies to uphold customer satisfaction and comply with regulatory requirements․ Its simplicity and effectiveness make it a vital tool for safeguarding product integrity and operational excellence․

Overview of Human Factors in Inspection Tasks

Human factors in inspection tasks encompass the physical, cognitive, and environmental elements that influence an inspector’s ability to detect defects accurately․ These factors include visual acuity, perception, attention, and decision-making abilities, which can vary significantly among individuals․ Environmental conditions such as lighting, noise, and workplace ergonomics also play a crucial role․ Organizational factors, like workload, training, and feedback mechanisms, further shape inspection performance․ Human factors are integral to understanding why inspection errors occur, as they highlight the limitations and variability inherent in human-centered processes․ Addressing these factors is essential to enhancing inspection accuracy and reliability, ensuring that inspectors operate under optimal conditions․ By recognizing and mitigating these influences, organizations can reduce errors and improve overall quality control outcomes․ This understanding forms the foundation for developing strategies to optimize inspection tasks and minimize human-induced failures․

Key Human Factors Influencing Visual Inspection

Human factors such as visual perception, cognitive biases, and environmental conditions significantly impact inspection accuracy and reliability, affecting how effectively defects are detected and addressed․

Visual Perception and Its Limitations

Visual perception, while crucial for detecting defects, has inherent limitations․ Factors like lighting conditions, spatial orientation, and visual acuity can affect an inspector’s ability to identify defects accurately․ For instance, poor lighting may obscure defects, while fatigue or stress can impair focus․ Additionally, the complexity of defect types and their distribution across surfaces can challenge even experienced inspectors․ Cognitive biases, such as confirmation bias, may lead to overlooking defects or misjudging their severity․ These limitations underscore the need for optimized environmental conditions, proper training, and ergonomic workplace design to enhance visual inspection accuracy and reduce human error in quality control processes․

Cognitive Biases and Decision-Making Errors

Cognitive biases significantly influence visual inspection tasks, leading to decision-making errors․ Inspectors may experience confirmation bias, where they overlook defects due to preconceived notions․ Time pressure and stress can impair judgment, causing misclassification of defects․ Additionally, cognitive overload from complex defect types or high defect probabilities can reduce accuracy․ Decision-making errors are further compounded by fatigue, which diminishes attention and focus․ Organizational factors, such as inadequate training or unclear standards, exacerbate these issues․ These biases and errors highlight the need for structured training programs and ergonomic improvements to mitigate their impact on inspection reliability and ensure consistent quality control outcomes․

Environmental Factors Affecting Inspection Accuracy

Environmental factors play a crucial role in visual inspection accuracy․ Lighting conditions, such as insufficient illumination or excessive glare, can obscure defects, making them difficult to detect․ Temperature and humidity levels may also affect inspector comfort, leading to fatigue and reduced focus․ Noise and distractions in the workplace can disrupt concentration, further impairing accuracy․ Additionally, the spatial orientation of the inspection area and the positioning of materials can influence an inspector’s ability to identify defects․ These environmental challenges underscore the importance of optimizing workplace conditions to enhance visual inspection effectiveness and reduce human error․

Organizational and Ergonomic Influences

Organizational and ergonomic factors significantly impact visual inspection accuracy․ Workload, time constraints, and insufficient training can lead to inspector fatigue and reduced focus․ Poor ergonomic design of workstations may cause physical discomfort, distracting inspectors and impairing their ability to detect defects․ Additionally, organizational support, such as providing clear guidelines and feedback mechanisms, plays a critical role in maintaining inspector performance․ Ergonomic tools and equipment, like magnifiers or proper lighting, can enhance visual acuity and reduce strain․ Addressing these factors is essential to minimizing human error and improving the overall effectiveness of visual inspection processes in industrial settings․

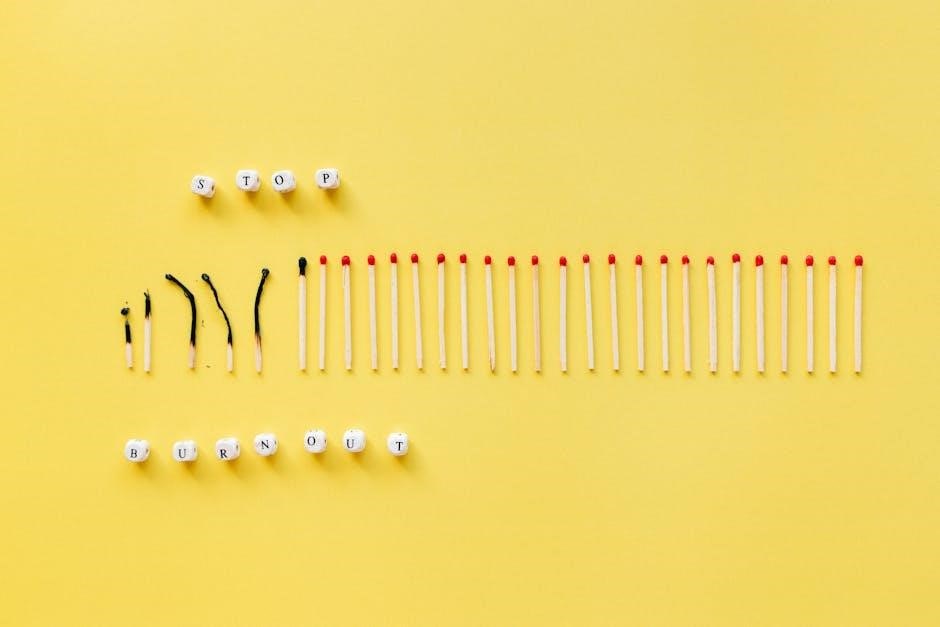

Consequences of Human-Induced Inspection Failures

Human-induced inspection failures can lead to compromised product quality, safety risks, and increased costs due to undetected defects, ultimately damaging consumer trust and organizational reputation․

Examples of Failures in Real-World Scenarios

Human-induced inspection failures have led to significant real-world consequences․ In aviation maintenance, oversight of critical cracks in aircraft components has resulted in accidents․ Similarly, in manufacturing, undetected defects like sand holes in castings have caused product recalls․ Medical device inspections have also failed due to missed defects, risking patient safety․ Automotive industries report cases where faulty parts passed inspection, leading to vehicle malfunctions․ Environmental factors, such as poor lighting, contributed to missed defects in construction materials․ Additionally, cognitive biases, like confirmation bias, have caused inspectors to overlook flaws․ These examples highlight how human limitations in visual inspection can lead to costly and dangerous outcomes, emphasizing the need for improved training and ergonomic practices to mitigate such failures․

Impact on Product Quality and Safety

Human-induced visual inspection failures significantly compromise product quality and safety․ Undetected defects can lead to product malfunction, posing risks to consumer safety and damaging brand reputation․ In industries like aerospace and automotive, overlooked flaws may result in catastrophic failures, endangering lives and incurring substantial financial losses․ Furthermore, such failures can lead to costly recalls, legal liabilities, and operational downtime․ The repercussions extend to supply chains, where defective products may disrupt production workflows․ Ensuring the reliability of visual inspections is thus critical to maintaining high safety standards and customer trust․ Addressing human factors through improved training and ergonomic practices is essential to mitigate these risks and enhance overall product quality and safety․

Addressing Human Factor Challenges

Mitigating human error in visual inspection requires targeted solutions, including enhanced training, ergonomic workplace adjustments, and the integration of Automated Visual Inspection systems to improve accuracy and efficiency․

Training and Skill Development for Inspectors

Effective training programs are crucial to minimize visual inspection failures․ These programs should focus on enhancing inspectors’ visual acuity, improving decision-making skills, and familiarizing them with defect types․ Regular workshops and practical exercises can boost accuracy․ Additionally, incorporating feedback sessions allows inspectors to learn from past errors, refining their techniques․ Training should also emphasize ergonomic practices to reduce fatigue, a known contributor to inspection errors․ By investing in comprehensive skill development, organizations can significantly reduce human-induced failures, ensuring higher product quality and safety standards․ Continuous learning and adaptation to new technologies, such as Automated Visual Inspection, further empower inspectors to perform their roles more effectively in evolving industrial environments․

Ergonomic Improvements in the Workplace

Ergonomic improvements play a vital role in reducing visual inspection failures by addressing physical and environmental stressors․ Proper lighting conditions, such as adequate brightness and minimal glare, are essential to prevent eye strain․ Workplace layout adjustments, including adjustable workstations and seating, can minimize physical discomfort and maintain focus․ Additionally, tools like magnifying glasses or digital aids can enhance visual clarity․ Regular breaks and task rotation help reduce eye fatigue and mental overload․ Implementing ergonomic standards ensures inspectors operate in a comfortable environment, improving their ability to detect defects accurately․ By prioritizing workplace ergonomics, organizations can significantly enhance inspection accuracy and overall product quality, ultimately mitigating the risk of human-induced errors in visual inspection tasks․

Implementation of Automated Visual Inspection (AVI)

Automated Visual Inspection (AVI) has emerged as a robust solution to mitigate human-induced errors in visual inspection․ By leveraging advanced technologies like high-speed cameras, artificial intelligence, and machine learning algorithms, AVI systems can detect defects with greater accuracy and consistency․ Unlike human inspectors, AVI is unaffected by factors such as fatigue, cognitive biases, or environmental conditions, ensuring reliable results․ These systems can process large volumes of data rapidly, identifying subtle defects that may escape human notice․ AVI also reduces variability and enhances repeatability, making it particularly valuable in high-stakes industries like manufacturing, aerospace, and healthcare․ While AVI does not entirely replace human inspectors, it significantly complements their roles by automating repetitive tasks and enabling them to focus on complex decision-making․ This integration of technology and human expertise represents a significant leap forward in improving inspection accuracy and overall product quality․

Feedback Mechanisms and Performance Monitoring

Feedback mechanisms and performance monitoring are critical for enhancing the effectiveness of visual inspection processes․ By implementing structured feedback loops, organizations can identify and address human factors contributing to inspection failures․ Regular performance assessments help measure inspectors’ accuracy and consistency, while providing insights into areas needing improvement․ Real-time feedback enables inspectors to correct errors promptly, reducing the likelihood of recurring mistakes․ Additionally, monitoring tools can track environmental and ergonomic conditions, ensuring optimal inspection settings․ Training programs, informed by performance data, can be tailored to address specific weaknesses․ Continuous monitoring fosters a culture of accountability and iterative improvement, ultimately leading to higher product quality and safety standards․ By integrating feedback and monitoring, organizations can systematically mitigate human-induced inspection failures and maintain competitive edge in quality control․

Research highlights that human factors significantly influence visual inspection accuracy, with limitations in visual perception, cognitive biases, and environmental conditions being primary contributors to failures․ Studies emphasize the role of ergonomics, workplace lighting, and inspector training in mitigating these issues․ Automated Visual Inspection (AVI) systems and feedback mechanisms have shown promise in reducing human error․ Organizational support and clear decision-making processes further enhance inspection reliability․ The interplay of these factors underscores the need for a holistic approach to improve inspection outcomes․ Addressing these challenges is critical for ensuring product quality, safety, and operational efficiency across industries․ Future advancements in AVI and ergonomic designs are expected to further minimize human-induced inspection failures, fostering more robust quality control systems․

Future Trends in Mitigating Human Factor Failures

Emerging technologies and methodologies are expected to revolutionize the mitigation of human-induced inspection failures․ The integration of Artificial Intelligence (AI) and machine learning algorithms into Automated Visual Inspection (AVI) systems will enhance accuracy and reduce reliance on human judgment․ Augmented Reality (AR) tools are anticipated to assist inspectors by providing real-time guidance, improving defect detection rates․ Additionally, advancements in ergonomic design and workplace optimization will address environmental and physical stressors, creating more conducive inspection conditions․ Training programs incorporating virtual reality (VR) simulations are expected to improve inspectors’ skills and reduce cognitive biases․ Furthermore, data analytics will enable predictive maintenance and performance monitoring, identifying potential human errors before they occur․ These trends collectively aim to create a more efficient, accurate, and reliable inspection process, minimizing the impact of human factors on quality control outcomes․